PSSA

Member News

NEWS

|

ISSUE 10 January 2016

– 6 –

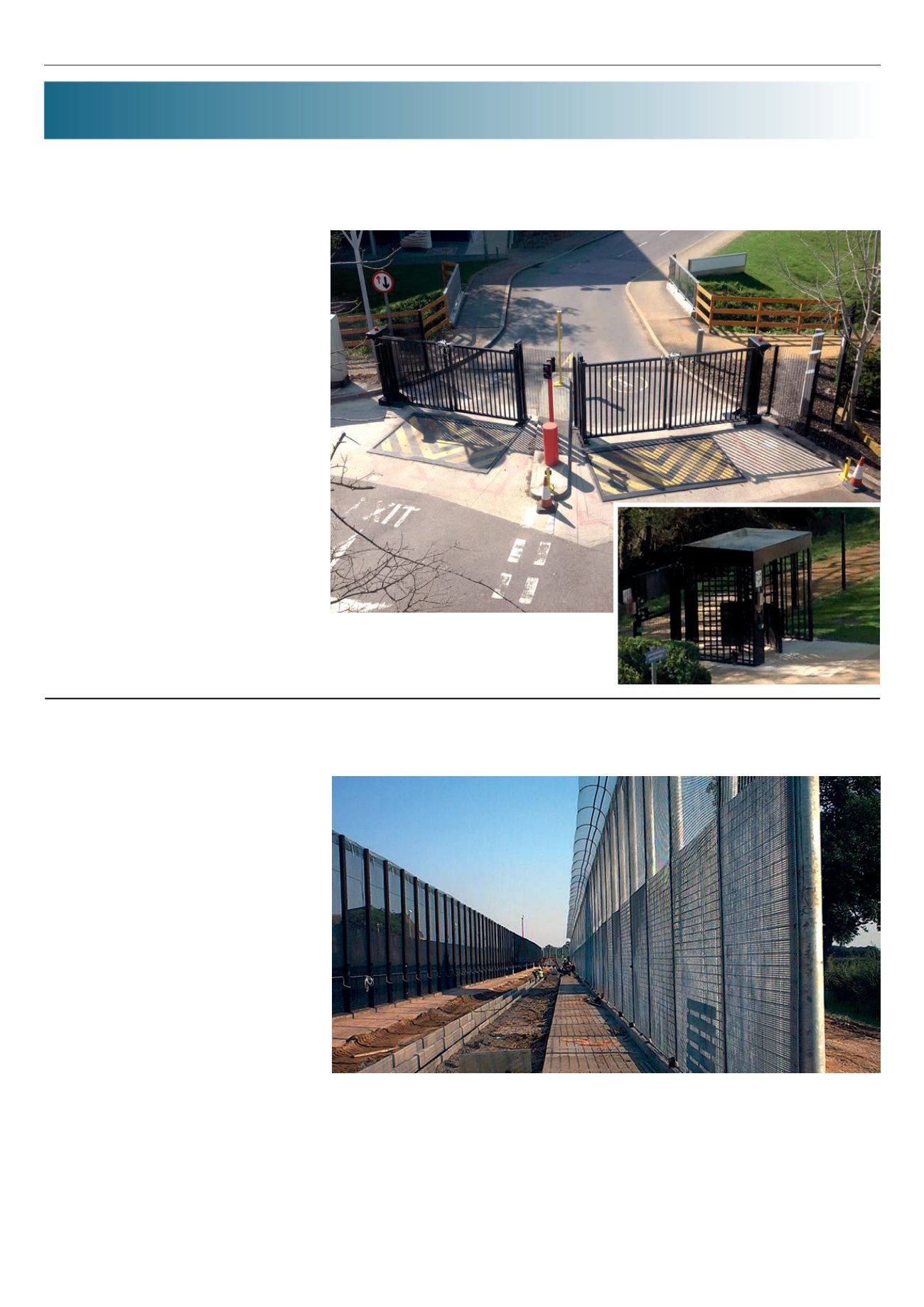

Gas network turns to prison style security

One of the UK’s largest gas distributors has

specified prison-style double skin steel mesh

and special fence toppings to secure its gas

distribution network across the north of England.

They have turned to PSSA member Zaun

group and its HiSec DualSkin and Flexible

Steel Topping (FST) products.

The distributor delivers gas to 2.7 million

homes and businesses and around 6.7 million

individuals in the North East, Northern

Cumbria and much of Yorkshire through a

vast network of 37,000km of gas pipes –

enough to stretch from Leeds to Sydney,

Australia and back again!

During periods of peak demand, the

network transports four times as much energy

as the electricity networks to large cities

such as Newcastle, Sunderland, Leeds, York,

Hull and Bradford and beautiful rural areas

including North Yorkshire and Cumbria.

Zaun’s HiSec DualSkin has been specifically

designed for sites that need a more secure

solution and features two layers of the

traditional HiSec 358 welded mesh with

76.2mm x 12.7mm open mesh sections.

These double skin 358 panels are welded

together with the secondary panel turned

90 degrees to make a very tight 12.7mm x

12.7mm mesh configuration, which is difficult

to cut and almost impossible to climb.

The tiny apertures eliminate foot and finger

holds for people trying to climb or gain access

to the site, prevent objects being passed

through and are highly resistant against the

use of hand or power cutting tools.

HiSec DualSkin conforms to BS1722 Part 14

Category 4 and has been extensively used in

prisons and by the Ministry of Defence (MoD)

to protect high security assets.

The FST topping system that tops the

fence is fully tested for use in UK high security

prisons. At the heart of FST is a steel mesh arch,

curved back over the top of a steel fence, fixed

to a flexible steel bracket that is designed to

move when people try to climb it.

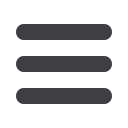

Zaun opens gates to ThamesWater

Perimeter fencing expert Zaun has installed

trackless bi-folding automatic speed gates at

a Thames Water administration building.

The vehicle gates – which incorporate

live-monitored safety edges, dual height

safety photocells and manual-disengaging

vertical infill bars – have replaced old rising

arm barriers at Kemble Court, Thames

Water’s Operations Management Centre

in Reading.

The PSSA member also installed an adjacent

pedestrian turnstile with a passage for bicycles

and integrated the installation into existing

fencing with 1.8m high HiSec fencing.

So pleased are Thames Water with the

vehicle gate solution that they have specified

it for one of their many sewage treatment

plants, at East Hyde in Luton, that operates

a combined heat and power (CHP) unit to

generate the electricity the plant needs.

The CHP process ‘brews and chews’ sewage

sludge to break down biodegradable material

creating biomethane, or biogas, while

methane from the sludge is burned to create

heat, which in turn generates renewable

electricity using a pre-treatment process

called thermal hydrolysis.

Zaun installed trackless bi-folding automatic vehicle

speed gates (above) and pedestrian turnstile (right)

at a Thames Water administration building.